Conestoga students develop assembly line to recycle plastics into drink coasters

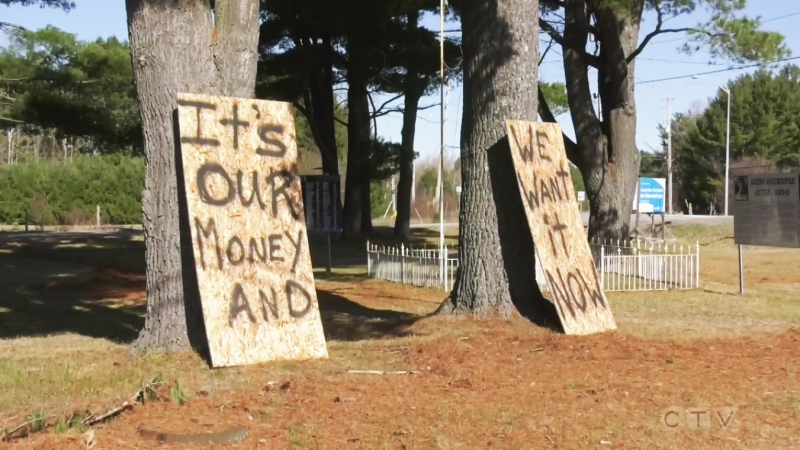

Team Stacked developed an automated manufacturing cell that recycles plastic into drink coasters for their mechanical engineering technology - robotics and automation program capstone project. (Conestoga College)

Team Stacked developed an automated manufacturing cell that recycles plastic into drink coasters for their mechanical engineering technology - robotics and automation program capstone project. (Conestoga College)

A team of final-year students in Conestoga’s mechanical engineering technology - robotics and automation program designed and built an automated manufacturing system with a focus on environmental sustainability.

Team Stacked has developed a fully-functioning assembly line to recycle high-density polyethylene (HDPE) plastic into drink coasters.

“The industry right now is focused on sustainability,” said Stacked team member Sherry Dai in a media release. “We wanted to reflect that in our capstone project and offer a solution.”

The system is designed to melt pre-shredded plastics in a heating tunnel before pressing and cutting to size. The coaters are then passed through a quality check and packaged.

The team sourced plastic from Concord Blow Molding and collaborated with Conestoga’s packaging engineering technician program for a custom box design and materials. The team won Best in Program for their system.

“We experienced a steep learning curve throughout the build phase. We were constantly getting hit with things we weren’t expecting and had to address quickly,” said Stacked team member Melissa Broda. “It was a challenge, but we got to see everything that goes into developing and building an automated system and it provided a well-rounded view of what to expect when we get into industry.”

For their final project, students in the program are required to create and present assembly lines that demonstrate deliverables such as programming, quality assurance, safety and product design.

In addition to Stacked, team Work From Home designed a process to manufacture and package wooden ping pong paddles.

“We were exposed to all aspects of building an automated system, including working in a large team, and going from the design phase to the build phase and working through the challenges provided great experience,” said Stacked team leader Andrew Knowles.

CTVNews.ca Top Stories

BREAKING New York appeals court overturns Harvey Weinstein's 2020 rape conviction from landmark #MeToo trial

New York’s highest court on Thursday overturned Harvey Weinstein’s 2020 rape conviction, finding the judge at the landmark #MeToo trial prejudiced the ex-movie mogul with improper rulings, including a decision to let women testify about allegations that weren’t part of the case.

BREAKING Monthly earnings rise, payroll employment falls: jobs report

The number of vacant jobs in Canada increased in February, while monthly payroll employment decreased in food services, manufacturing, and retail trade, among other sectors.

Doctors say capital gains tax changes will jeopardize their retirement. Is that true?

The Canadian Medical Association asserts the Liberals' proposed changes to capital gains taxation will put doctors' retirement savings in jeopardy, but some financial experts insist incorporated professionals are not as doomed as they say they are.

Secret $70M Lotto Max winners break their silence

During a special winner celebration near their hometown, Doug and Enid shared the story of how they discovered they were holding a Lotto Max ticket worth $70 million and how they kept this huge secret for so long.

Remains from a mother-daughter cold case were found nearly 24 years later, after a deathbed confession from the suspect

A West Virginia father is getting some sense of closure after authorities found the remains of his young daughter and her mother following a deathbed confession from the man believed to have fatally shot them nearly two decades ago.

Something in the water? Canadian family latest to spot elusive 'Loch Ness Monster'

For centuries, people have wondered what, if anything, might be lurking beneath the surface of Loch Ness in Scotland. When Canadian couple Parry Malm and Shannon Wiseman visited the Scottish highlands earlier this month with their two children, they didn’t expect to become part of the mystery.

Metro Vancouver mayors call for serial killer Robert Pickton to be denied parole

A dozen mayors from around Metro Vancouver say federal Attorney General and Justice Minister Arif Virani should deny parole for notorious B.C. serial killer Robert Pickton, and reassess the parole and sentencing system for 'prolific offenders and mass murderers.'

What do weight loss drugs mean for a diet industry built on eating less and exercising more?

Recent injected drugs like Wegovy and its predecessor, the diabetes medication Ozempic, are reshaping the health and fitness industries.

2 military horses that broke free and ran loose across London are in serious condition

Two military horses that bolted and ran miles through the streets of London after being spooked by construction noise and tossing their riders were in a serious condition and required operations, a British government official said Thursday.